|

|

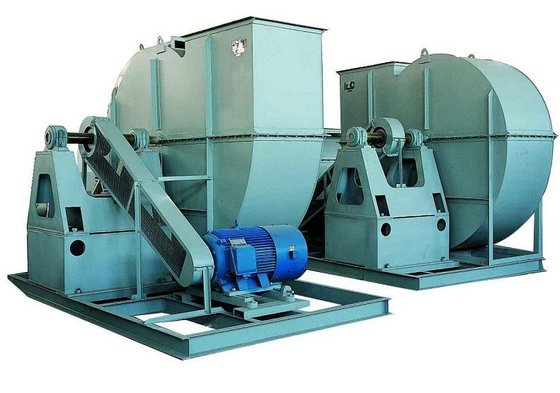

Industrial process and OEM fans and blowers for heavy industrial

applications.

|

|

Air

/ gas moving systems for high performance commercial and industrial

processes.

|

|

Industrial pressure blowers, commercial ventilation fans,

high-temperature industrial centrifugal pressure blowers, Buffalo

Blower pressure blowers Canadian Blower OEM industrial fans, roof and

wall exhausters, ventilating and air-conditioning equipment, pressure

blower HVAC, heating ventilation and air conditioning, industrial

process and OEM blowers, Buffalo Blower custom built fans, ventilators,

high temperature plug fans, combustion air blowers, Buffalo Blower oven

circulation fans.

|

|

|

|

Commited to the

outstanding customer service and the highest level of customer's

satisfaction.

|

|

|

|